PHILIPPE BOLTON

HANDMADE RECORDERS & FLAGEOLETS

HOW TO KEEP THE TENONS OF A WOODEN RECORDER IN GOOD CONDITION

The joints of a woodwind must be absolutely airtight. Any leak will deteriorate the sound quality.

To keep them in good condition they should be greased from time to time with vaseline or cork grease available in good music shops.

You can also make up a mixture of equal quantities vaseline and beeswax gently melted together in a bain-marie (a recipient

heated in boiling water) and allowed to set..

Thread joints

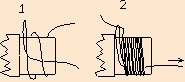

You can repair or adjust thread joints yourself. If they become too loose it is often sufficient to add a little thread. If they are too tight you can take some off. For this you can use buttonhole silk or polyester which you wax with beeswax. Simply pull the thread across the wax. It should then stick to the joint. Be careful not to put on too much thread or there could be a risk of splitting the instrument. Check this by carefully trying to assemble the recorder as you go along. After much use it can become necessary to change the joint completely. Cut away the old thread without touching the wood, and wind on some new waxed thread (cf drawing below). Begin by laying a loop lengthwise along the tenon, continue wrapping the thread around it, keeping the layer as regular as possible. As before, be careful not to put on too much. To secure the joint just pass the end through the loop and pull it back under the joint.

|

|

You can also secure the joint by using a needle to pass the end under the outer layers, in which case the initial loop is not necessary..

Warning, the joint must be made tight enough not to slip on the tenon. If this happens it could cling to the socket and make the instrument

very difficult to take apart.

Cork joints

A defective cork joint is more difficult to deal with. If the cork has become too loose, it can be temporarily restored to its original thickness

by very quickly heating it with a lighter flame (be careful not to burn the wood). However the effect of this will not last long. Alternatively a

little thread can be wound around the joint to make it thicker. However, sooner or later the joint will have to be replaced.

The easiest way of doing this is to cut away the cork and to make up a thread joint instead, as described above.

Making a new cork joint is more complicated. This is best done by a competent instrument repairer.

However, if you have to do it yourself, first find a sheet of cork of the right thickness. Next cut from this a rectangle of the same width and the same length as the

circumference of the groove in the tenon. This can be determined with a tape measure, or by calculation using the formula 2πR where π = 3.142

and R = half the diameter as measured with callipers. Fix the cork onto the tenon with contact glue. If the joint is too tight sand it with 150 grit abrasive paper

without touching the wood.